When it comes to tshirt printing in Singapore, silkscreen printing remains one of the most trusted methods in the industry. Known for its durability, vibrant colours, and versatility, silkscreen printing has long been the go-to option for brands, schools, events, and corporate clients. Among the different styles of silkscreen printing, CMYK silkscreen printing stands out for its ability to produce full-colour, photorealistic designs.

What is CMYK Silkscreen Printing?

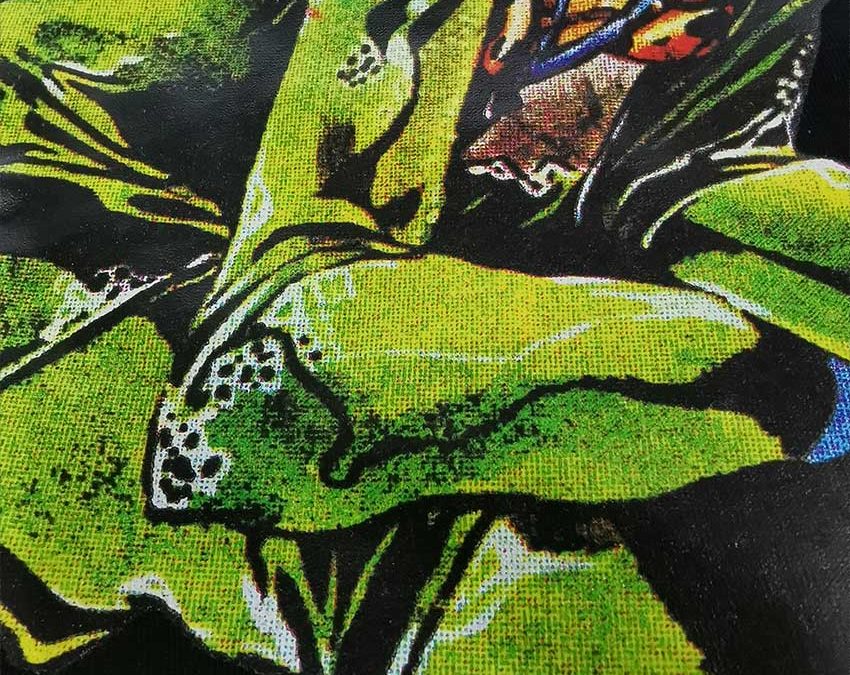

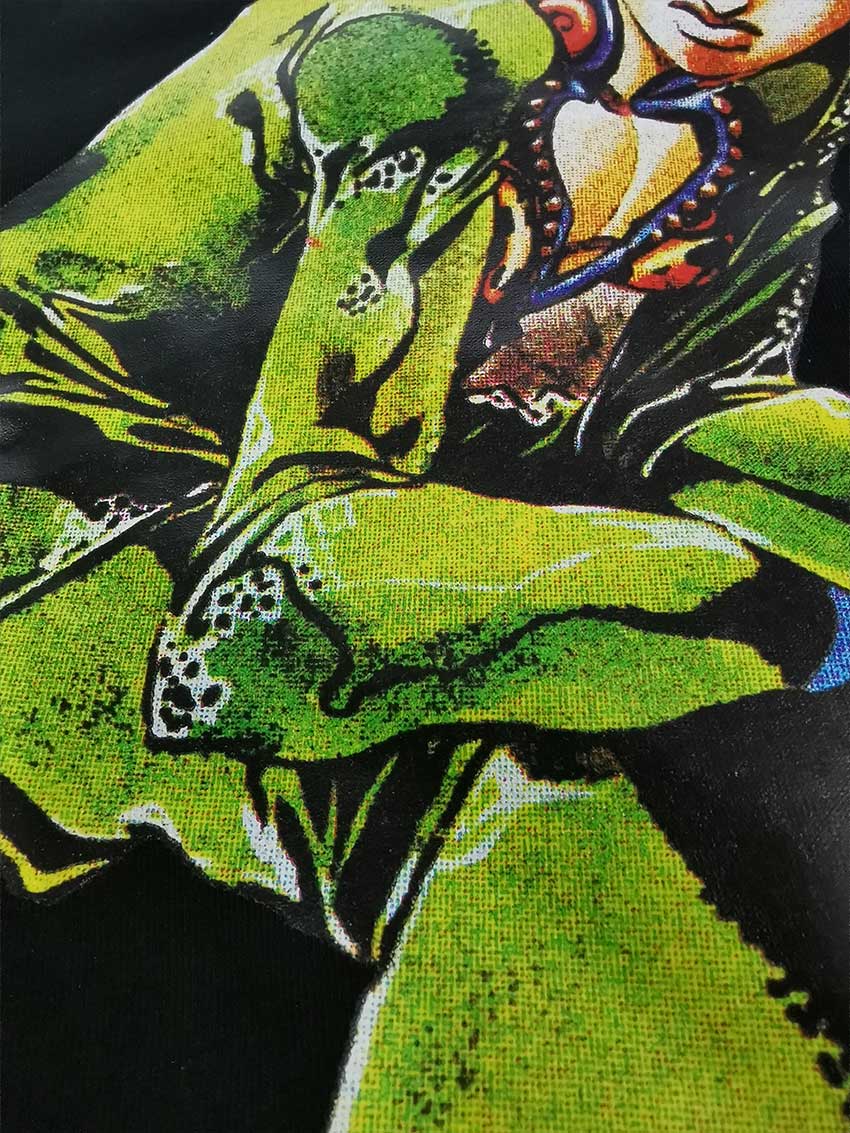

CMYK silkscreen printing uses four ink colours — Cyan, Magenta, Yellow, and Black (Key) — to reproduce full-colour images on garments. Each colour is printed separately in layers using halftone dots, blending together to create detailed, multicolour artwork. This technique is ideal for t-shirts that require gradient tones, photo-like prints, or artwork with many shades and colour variations.

Compared to standard spot colour printing, which uses solid blocks of colour, CMYK silkscreen printing allows for much more complex and artistic results.

Why Choose CMYK Silkscreen Printing?

- Photo-Realistic Quality

CMYK printing is perfect for designs with gradients, shadows, and photographic images — such as landscapes, portraits, or digital artwork. - High Durability

Just like traditional silkscreen methods, CMYK prints can last through many washes without fading, making it a reliable choice for long-term use. - Ideal for Bulk Orders

CMYK silkscreen printing is cost-effective for large quantities, making it a great option for apparel brands, marketing campaigns, or school tees. - Versatility Across Colours

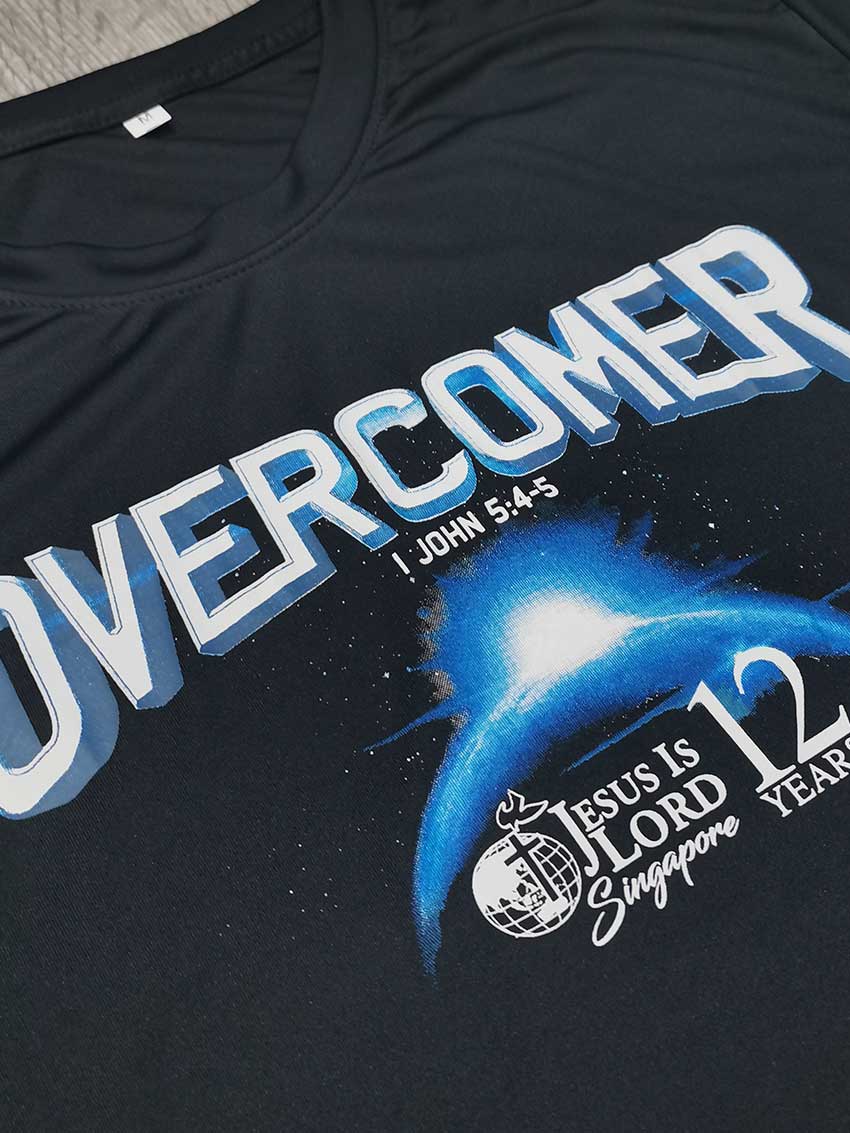

While best suited for white or light-coloured shirts, with the right base layers and adjustments, CMYK printing can also be done on darker garments.

CMYK vs DTG Printing

In Singapore’s competitive tshirt printing scene, CMYK silkscreen printing is often compared to Direct-to-Garment (DTG) printing. While DTG is quicker for small quantities and complex full-colour prints, CMYK silkscreen has the edge in cost and print longevity for bulk orders.

If you’re looking to print 50 or more pieces, and want vibrant, lasting colours — silkscreen printing is your best bet.

CMYK Silkscreen Printing in Singapore: Where to Start?

There are many silkscreen printing Singapore service providers, but finding one that specialises in CMYK silkscreen printing can make a big difference in your final result. At [Your Company Name], we offer professional CMYK silkscreen printing with attention to detail, print quality, and garment selection. Whether you’re creating merchandise, corporate gifts, or a fashion line, we can bring your designs to life.

? When CMYK Silkscreen Printing Uses More Than 4 Colours

1. Spot Colour Additions

Sometimes, in addition to CMYK, spot colours are added to achieve more accurate or vibrant results — especially when:

-

The design includes brand-specific Pantone colours that CMYK can’t replicate accurately.

-

There are neon, metallic, or fluorescent inks needed.

-

A very bright red, deep blue, or specific tone can’t be properly rendered using just CMYK inks.

So in these cases, CMYK becomes CMYK + Spot Colours, turning it into a 5-colour, 6-colour, or even more screen setup.

2. White Underbase on Dark Garments

For printing on black or dark fabrics, a white base layer is usually added beneath the CMYK colours to ensure vibrancy. This adds an extra screen, making it a 5-colour process:

-

White underbase

-

Cyan

-

Magenta

-

Yellow

-

Black

This underbase is crucial for maintaining colour accuracy, especially since CMYK inks are translucent.

3. Custom Extended Gamut Printing

Some advanced screen printers use an expanded colour gamut, adding extra inks like Orange, Green, or Violet (often referred to as CMYKOGV) to achieve more vibrant or complex images beyond the standard CMYK range.

However, this is rare and used mainly in high-end or art-grade silkscreen production.