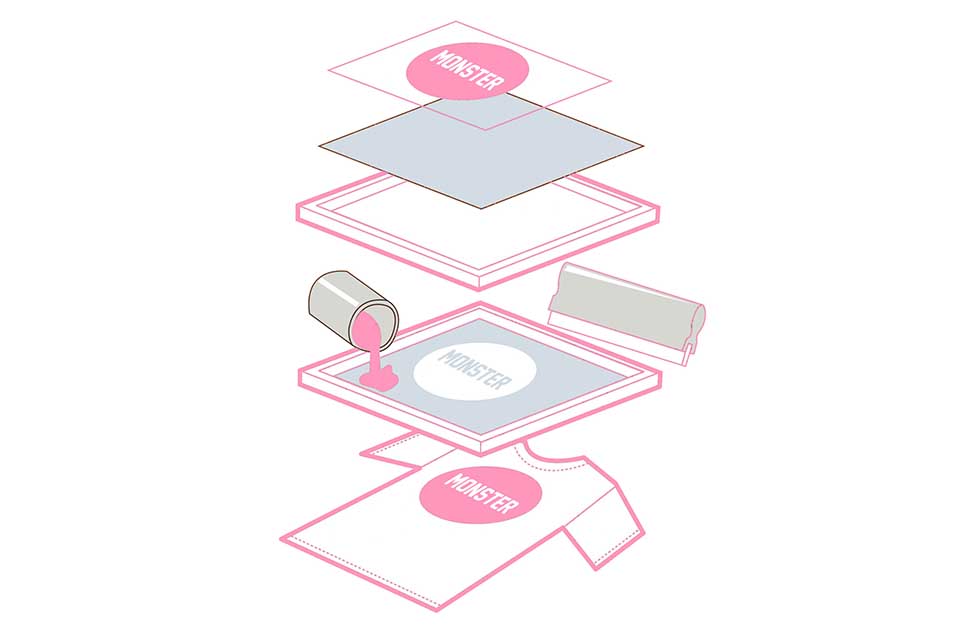

What is Silkscreen Printing?

Silkscreen Printing is a design stencil and print method that involves printing ink through stencils that are supported by a porous fabric mesh stretched across a frame called a screen. Ink gets “pushed” through the sreen mesh and onto apparels, creating your desired silkscreen print design.

We have since introduced more varieties of silkscreen print techniques that can achieve special effect prints to suit your needs.

CMYK Silkscreen Print

CMYK silkscreen printing is a variation of traditional silkscreen printing that uses the CMYK colour model. CMYK stands for Cyan, Magenta, Yellow, and Key (Black), which are the four primary colours used in printing.

In CMYK silkscreen printing, the design is separated into four different colour layers: Cyan, Magenta, Yellow, and Black. Each colour layer is printed separately using a mesh screen and the corresponding ink colour. By layering these four colours on top of each other, a wide range of colours can be achieved, including full-colour or multi-colour designs.

The process of CMYK silkscreen printing is similar to traditional silkscreen printing. A mesh screen is prepared for each colour layer, with the design areas blocked off to allow ink to pass through. The screens are then aligned and printed one at a time, starting with the lightest colour (usually Yellow) and ending with the darkest colour (Black). The ink is pushed through the silkscreen mesh onto the fabric, creating a layered print.

CMYK silkscreen printing is commonly used for reproducing full-colour or multi-colour designs with a high level of detail. The process allows for accurate reproduction of complex designs.

One advantage of CMYK silkscreen printing is its ability to achieve a wide range of colours using only four ink colours. This makes it a good option for printing full-colour designs compared to using spot colors.

However, CMYK silkscreen printing does have some limitations. It may not be suitable for designs that require very vibrant or specific colours that cannot be achieved using the CMYK colour model. Additionally, the process can be time-consuming and requires careful alignment of the colour layers to ensure accurate registration.

In summary, CMYK silkscreen printing is a variation of traditional silkscreen printing that uses the CMYK colour model to reproduce full-colour or multi-colour designs. It offers a precise method for printing complex designs with a high level of detail. However, it may have limitations in achieving specific or vibrant colours and requires careful alignment during the printing process.

Apparels suitable for CMYK silkscreen print: custom made items.

Puff Silkscreen Print

The puff silkscreen print creates a raised, textured effect by using a special ink that expands when heated, while silkscreen printing involves pushing ink through a mesh screen onto the fabric. Puff silkscreen print is ideal for adding dimension and texture to designs, while silkscreen printing is better for intricate and detailed designs. Both silkscreen print techniques have their advantages and can be used for various applications. The article also provides tips on choosing the right silkscreen print technique based on design requirements and fabric type. In addition to the differences in the printing process, there are also differences in the final appearance and feel of the printed design.

Puff silkscreen print creates a three-dimensional effect with a raised texture. The ink expands when heated, creating a puffy or raised appearance. This gives the design a tactile feel and adds depth to the printed image. Puff silkscreen print is often used to create bold and eye-catching designs that stand out.

On the other hand, silkscreen printing produces a flat, smooth print. The ink is pushed through a mesh screen onto the fabric, resulting in a crisp and detailed design. Silkscreen printing is known for its ability to reproduce intricate patterns and fine details accurately. It is commonly used for printing logos, text, and complex designs.

When choosing between puff silkscreen print and silkscreen printing, there are a few factors to consider.

Firstly, the design itself plays a significant role. If the design requires a raised texture or a three-dimensional effect, then puff print would be the better choice. Puff print is particularly suitable for designs that need to stand out and have a tactile feel.

Secondly, the fabric type should be considered. Puff silkscreen print works best on fabrics with a tight weave, such as cotton or polyester. Silkscreen printing, on the other hand, can be used on a wide range of fabrics, including cotton and polyester.

Lastly, the desired durability of the print should be taken into account. Puff silkscreen print tends to be less durable than silkscreen printing. The raised texture of puff print can wear off over time, especially with frequent washing. Silkscreen printing, on the other hand, is more resistant to fading and peeling, making it a better choice for long-lasting designs.

In conclusion, puff silkscreen print and silkscreen printing are two different techniques with distinct characteristics. Puff silkscreen print creates a raised, textured effect, while silkscreen printing produces a flat, detailed print. The choice between the two depends on the design requirements, fabric type, and desired durability of the print. Both techniques offer unique advantages and can be used to create stunning designs on various types of fabric.

Apparels suitable for Puff silkscreen print: custom made items.

Neon Silkscreen Print

Neon silkscreen printing is a specialized technique that involves using neon-coloured inks in the silkscreen printing process. Neon colors are bright, vibrant, and highly saturated, making them stand out and grab attention. This printing technique is often used to create eye-catching designs and signage.

The process of neon silkscreen printing is identical to traditional silkscreen printing. A mesh screen is prepared with the design areas blocked off to allow the neon ink to pass through. The ink is then applied to the screen and pushed through onto the fabric or substrate using a squeegee. The neon ink creates a bold and vibrant print that is highly visible.

Neon silkscreen printing offers several advantages. Firstly, it allows for the creation of designs with intense and vibrant colours that cannot be achieved with standard inks. Neon colours, such as fluorescent pinks, yellows, greens, and oranges, have a high visibility and can make a design pop.

Secondly, neon silkscreen printing is versatile and can be used on various types of fabric.

However, there are a few considerations when using neon silkscreen printing. Neon silkscreen inks tend to be more translucent than standard inks, so they may require multiple layers or a white base layer to achieve full opacity and vibrancy. Additionally, neon inks may have different drying and curing requirements compared to standard inks. However with trained and professional silkscreen printers, these will not be a problem in the neon silkscreen printing production process.

Neon silkscreen print can create striking and attention-grabbing designs that are perfect for events, promotions, or any application where visibility is key. The vibrant and bold colours of neon inks make them a popular choice for creating designs that stand out and make a statement.

Apparels suitable for Neon silkscreen print: custom made items.

Reflective Silkscreen Print

Reflective silkscreen printing is a specialized technique that involves using reflective inks in the silkscreen printing process. This type of printing creates designs that reflect light, making them highly visible in low-light or nighttime conditions. Reflective silkscreen printing is commonly used for safety apparel and designer wear for a bold and catchy look.

The process of reflective silkscreen printing is similar to traditional silkscreen printing. A mesh screen is prepared with the design areas blocked off to allow the reflective ink to pass through. The ink is then applied to the screen and pushed through onto the fabric or substrate using a squeegee. The reflective ink contains tiny glass beads or reflective particles that reflect light when illuminated.

Reflective silkscreen printing offers several advantages. Firstly, it enhances visibility and safety in low-light or nighttime conditions. The reflective properties of the ink allow the printed design to reflect light, making it highly visible to others.

Secondly, reflective silkscreen printing can be used on all types of fabric. This makes it suitable for a wide range of designs or different purposes.

However, there are a few considerations when using reflective silkscreen printing. Reflective inks may have different drying and curing requirements compared to standard inks, but in the hands of professional and trained silkscreen printers, this is not an issue. Additionally, the reflective properties of the ink may diminish over time with wear and washing, so it is important to take proper care of the printed items to maintain their reflective capabilities. An alternative to reflective prints will be reflective strips sewn onto apparels (can be done via custom made order) or reflective vinyl heat transfer printing. The latter techniques are able to retain their reflective properties better, compared to reflective silkscreen printing.

Reflective silkscreen printing is an effective way to enhance visibility and safety in low-light or nighttime conditions. The reflective properties of the ink make the printed design highly visible when illuminated, making it a popular choice for safety apparel and bold design elements . Reflective silkscreen printing can help ensure that your designs are seen even in challenging lighting conditions.

Apparels suitable for Reflective silkscreen print: custom made items.